InCiTe™ micro-CT and Manufacturing

Why are bubbles a problem?

When manufacturing parts, there is always a chance of pores or holes forming within them during the process. Voids can affect the quality of goods being manufactured, and this is a big concern.

In die casting, for example, air can be trapped in molds and cause bubbles inside the molten metal. Gas micro porosity can take place in deeper sections of a part. With plastics, bubbles can also form in molding. In fact, bubbles are a known cause of cosmetic rejects. This costs manufacturers time and money, and the process to discover and repair issues can be lengthy.

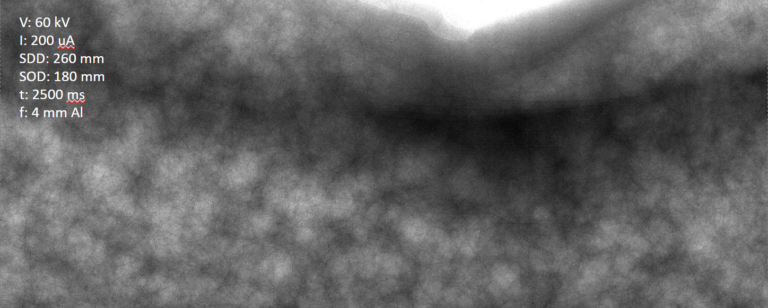

With KA Imaging’s InCiTe™ micro-CT, high-quality images of materials can be taken to visualize bubbles and support manufacturing needs. In fact, it can even show the bubbles in a chocolate bar.

InCiTe™ micro-CT uses phase contrast technology and allows for better visualization of materials. The BrillianSe™ X-ray camera enables rapid phase contrast imaging and conventional micro-CT in a portable benchtop system.